The Noise Guard is available in a range of different configurations to suit your application. With monitoring solutions for noise and weather data, we can optimize your costs to deliver the data that you need. Mobile configurations are useful where noise and/or vibration monitoring needs to regularly relocate as work changes, or as road work machinery progresses along their path. New location is automatically updated on the server and available for the end user.

Environmental noise measurements and reporting according to local legislation

Stand-alone noise monitoring or integration into large-scale projects via API

Industrial noise monitoring and compliance with local or regional regulations

Notification for exceeded noise limits with user-definable threshold levels

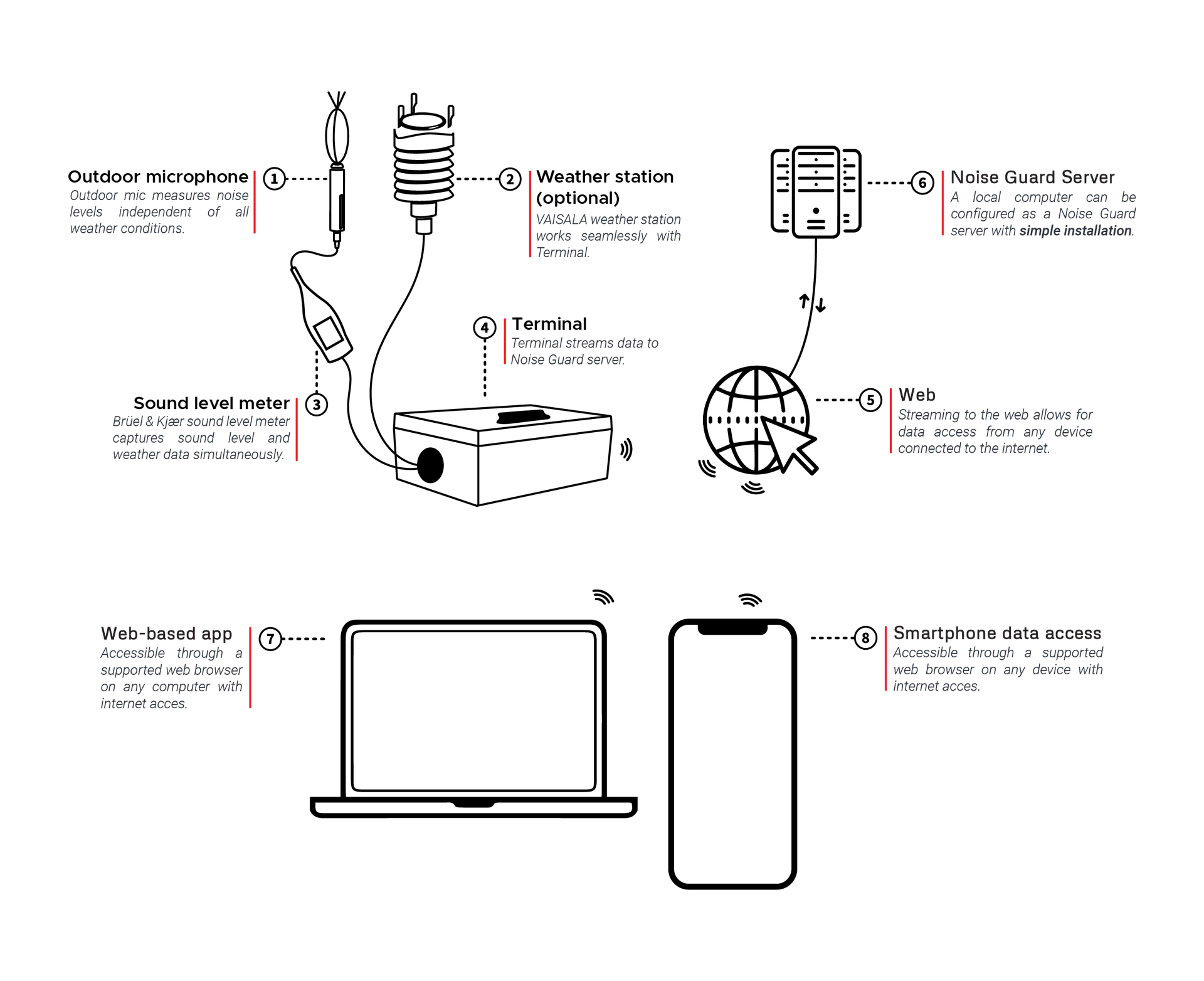

Noise measurements are based on our proven hardware, which continuously monitors noise at several locations around the world in a variety of applications including industrial sites, ports, racetracks and construction sites.

Equipped with an outdoor microphone, the stationary system is designed for outdoor use over the course of many years, measuring noise levels in accordance with all applicable international standards.

Communication to the Internet is made via the LTE/4G wireless router or wired broadband installed in each terminal. If the communication link breaks down for any reason, all the data are stored locally and are uploaded when the link is re-established.

Data are stored locally on the terminal and continuously transferred to the Noise Guard server. Local storage is crucial to avoiding data loss in the eventuality of a communications failure.

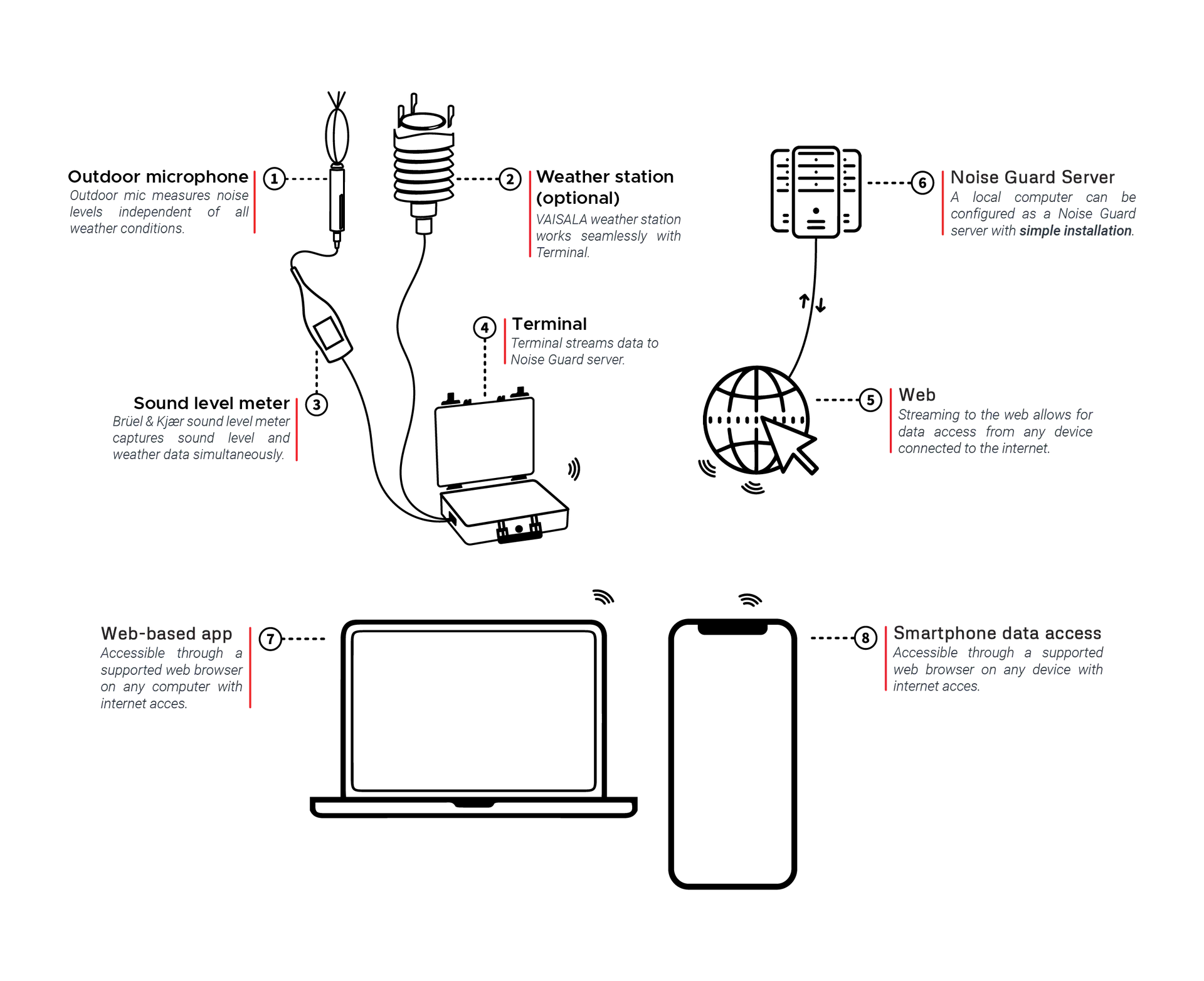

Portable noise monitoring is provided with a portable unit. This is functionally equivalent to the stationary version, but housed in a hand-carried waterproof case, suitable for monitoring periods of several months at a time. Also equipped with a 4G digital router, the portable unit communicates noise data in real time to the Noise Guard server for storage and analysis.

Portable terminals may be relocated during the course of a measurement programme. This is a simple process that requires notifying Noise Guard to stop gathering data at the current location, relocating the monitoring equipment and finally instructing Noise Guard to continue. The terminal’s location is automatically updated on the server with the new coordinates from the GPS installed inside the case.

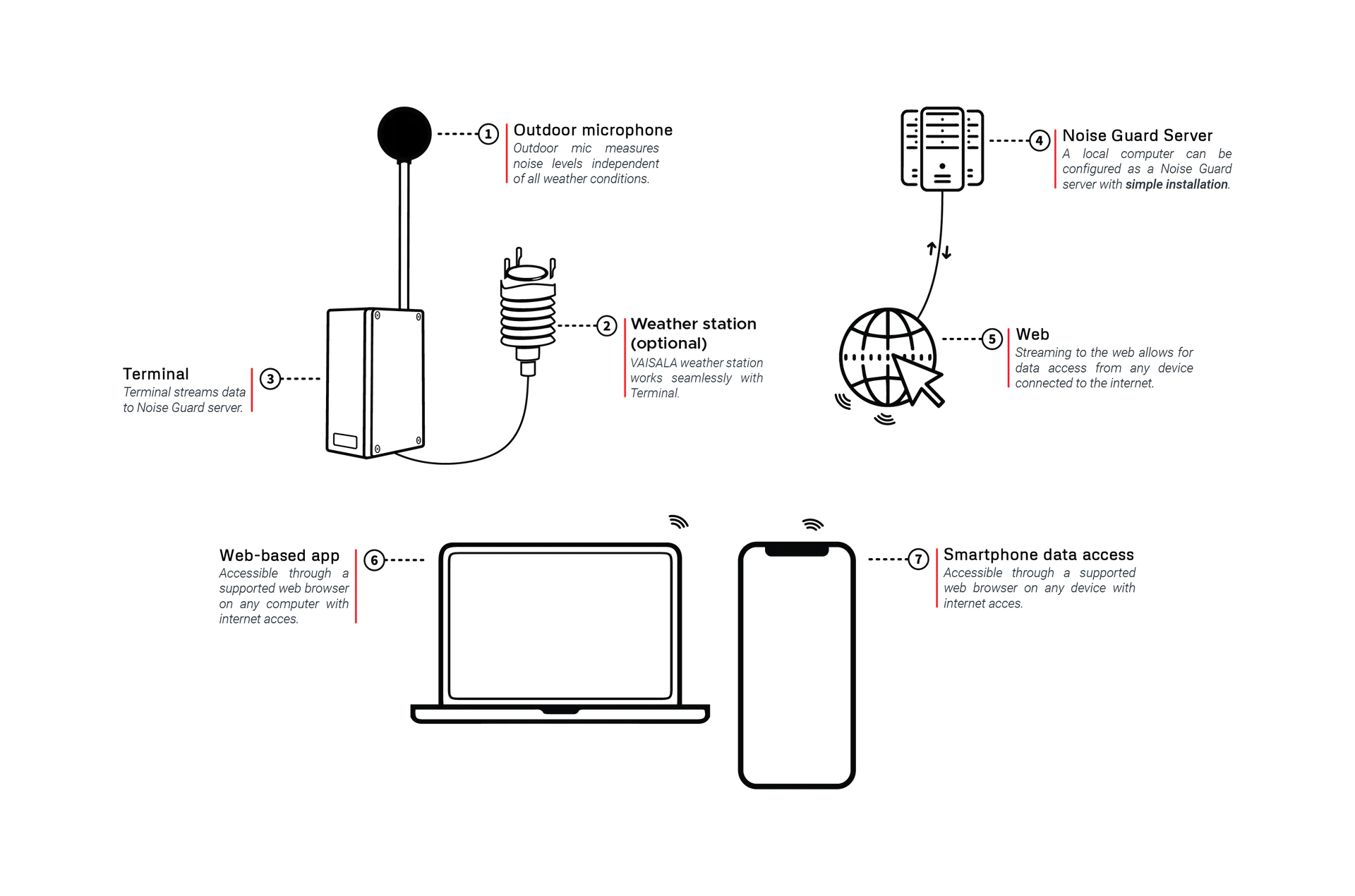

Noise Guard IoT is a unique, class 2 noise monitoring solution. The system is based on an in-house developed sound level meter framework and includes all of the functionalities that our class 1 terminal provides. Designed for continuous periodic measurements of basic sound parameters and the calculation of environmental noise indicators, this affordable system can be easily integrated into existing configurations to provide an expanded web of terminals.

Developed by a team with proven expertise in acoustics engineering and programming alike, Noise Guard IoT ensures a tailored approach to noise monitoring, demonstrating our commitment to quality and innovation. Noise Guard IoT offers assurance to both regulators and communities that your operation is under precise surveillance.

Running cables for power and communications to monitoring equipment around a construction site or industrial facility can be dangerous and unreliable. In suitable locations, stand-alone equipment may be provided, operating from solar panels and batteries. When coupled with mobile communications, this provides the best approach to ensure wire-free continuous monitoring around the site.

The battery pack is designed to provide true portability to the portable Noise Guard solution. The power pack uses the latest LiFePo technology to ensure long battery life in a lightweight and durable hand-carried case. Fully loaded battery pack can power our Noise Guard for up to 8 days of continuous operation. Operating lifetime can be reduced due to low temperature and use of accessories (communication, Weather station, GPS) The light weight pack means that you can easily transport your equipment and measure reliably in even the remotest locations.

Noise monitoring equipment must be calibrated every 12 months according to the ISO recommendation. Noise Guard may be accompanied by tailored preventative maintenance and calibration programme (depending on what is being monitored, and to which standards).

Brüel & Kjær/IMS staff or agents attend each monitoring location annually to undertake a range of checks and actions designed to ensure correct operation. In accordance with international standards and best practice, equipment will be field calibrated where practical and swapped out for laboratory calibration where not. All calibrations are traceable to international standards.